Automotive

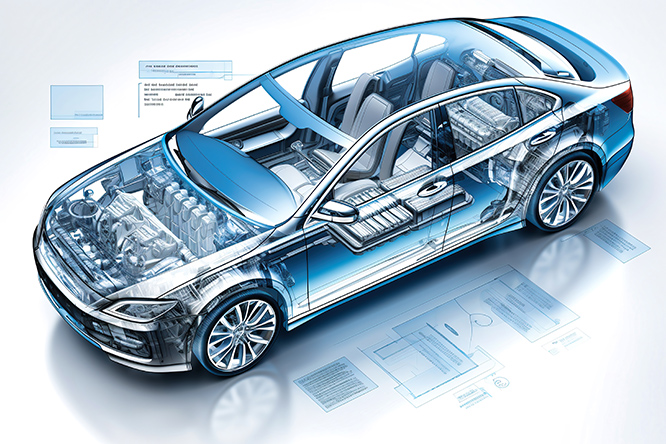

We contribute to the future of automobiles, handling everything from vehicle design to production engineering for manufacturing processes.

We are currently in the midst of a once-in-a-century revolution in the automotive industry. The value of automobiles as mere transportation is being reevaluated. Automobiles are becoming more diverse, and we need to transform them into a form of mobility that is integrated within social systems. For more than 60 years, TAMADIC has developed design and production engineering capabilities that are important for automobile manufacturing. We are committed to achieving carbon neutrality by 2050 as we focus all our effort toward solving the issues that currently face the automotive world and to achieve a mobility-oriented society in the future through our engineering capabilities.

Highlights

We provide total support for automotive development and production, from the development of vehicle layouts, body parts, interior and exterior parts, electronic components, and advanced driver-assistance systems to production line process and equipment design, layout investigation, production control system software and mold design, specialized equipment and machining/assembly/measurement jig design and fabrication, and line setup. We can design and deliver whatever systems are most suitable for the customer’s needs.

Vehicle Development (Product Development)

We are extensively involved in automotive product design and development, as described below.

- Overall vehicle layout investigation as well as performance design for improving collision safety, quietness, and other features of vehicle body structure that are important for performance

- Component design, including the body panels, platform panels, interior parts (such as instrument panels), exterior parts (such as bumpers), suspension, vehicle harnesses, auxiliary components (such as dashboard cameras) and other components that make up the structure of the vehicle

We are also involved in aspects of automotive development that will be even more important going forward:

- Electric vehicle (EV) motive power unit component design

- Development of software control for advanced driver-assistance systems (ADAS) and autonomous driving vehicles

In the future, we will continue to expand our automotive product development and pursue greater competitiveness in the field of automobiles, which are a key Japanese industry.

Production Engineering

This is a technical field in which we come up with methods of efficiently manufacturing high-quality yet inexpensive vehicles, which are a constantly evolving product, and apply those methods to production. This applies to a diverse array of services within a broad business domain, including vehicle body and drive unit product lines, investigation and planning of production line processes, production line setup, design and manufacture of production equipment, production information system design, labor-saving design and automation, and various product analysis services. The production engineering capabilities we have developed over many years have made significant contributions to Japanese vehicle manufacturing in the past, and they continue to do so today.

Forklifts and Special Vehicles

We conduct development and equipment design for special vehicles that require advanced technical development capabilities, ranging from parts design, diverse jig design, and automotive assembly control system design to mold design, mold machining NC data design, the design of welding/machining/assembly jigs, and the design and fabrication of specialized equipment.

Information Systems

We assist customers with digitalization by devising and proposing information management systems that play an important role in production, such as traceability systems for product manufacturing, development and verification services for the creation of digital twins, and information control systems for upstream processes as well as end users.

Technical Domains

Vehicle Development

- Vehicle design and layout design

Cabin layout design

Engine compartment layout and floor layout design - Vehicle body design

Body panel part design and underbody/chassis/roof/pillar design

Design of sound-absorbing material for bodies - Chassis design

Suspension design - Interior design

Cockpit design – instrument panels and consoles

Instrument panel layout planning and design

Interior trim design

Seat design

- Exterior design

Bumper design

Lamp design

Wiper design - Other – interior/exterior resin component design

- Auxiliary component design

- Vehicle harness design and layout design

- Autonomous driving related

- Futuristic ITS component layouts for self-driving

- Advanced driver-assistance system development

- Creating 3D model data for vehicle parts

Production Engineering

- Production equipment – design and fabrication

Body welding equipment and jigs

Vehicle assembly equipment and jigs

Vehicle component production equipment

Electric vehicle production equipment

Conveyance, measurement, and inspection equipment

Machining, assembly, and measurement jigs - Various types of design

Production equipment and machine design

Production equipment controller design

Die-casting die and press mold design

Production control system software development

3D modeling

- Various types of analysis

Electric vehicle analysis

Press molding analysis

Paint analysis

Robot simulations

Process simulations - Production engieering

Process planning, equipment planning, and layout design

Production line engineering, from planning to launch

Digital engineering

Concurrent engineering - Development

Production technology development