We make diverse contributions to the world’s most advanced technical fields, from product development to rocket operations support.

Rockets, satellites, and aircraft, which contain approximately 3 million components, demand the highest degree of precision and reliability to manufacture. Aerospace is the pinnacle of high-value-added industries and is famous for the technological spillover effect it has on other industries. Since its establishment, TAMADIC has been involved in the development and manufacture of Japanese aircraft and rockets as one of the companies helping to develop the aerospace industry. New aircraft and space-related development is planned for the future as well. From product development and R&D to product design and production equipment (production engineering), TAMADIC prides itself on being on the cutting edge thanks to its comprehensive capabilities.

Highlights

Nagoya is the industrial heartland of the Japanese aerospace sector, where the majority of rockets and aircraft are produced. TAMADIC personnel are involved in development projects right from the initial stages, contributing to airframe design, equipment design, analysis and simulation of various kinds, product development that makes use of software technologies, and production equipment design and fabrication. Numerous employees are also engaged in rocket launch support operations at the Tanegashima Space Center.

Product Development

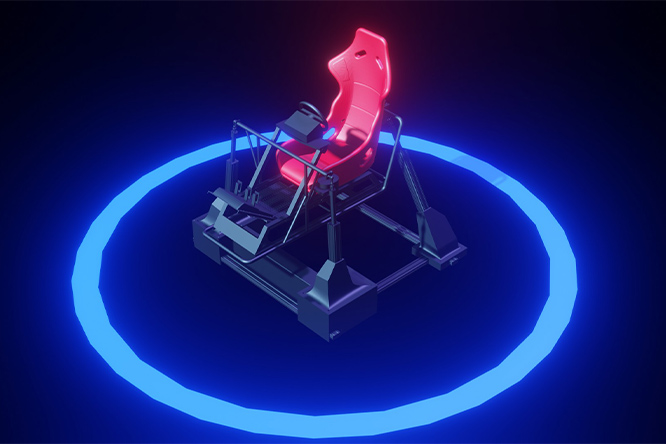

We develop and sell our own flight training device (FTD), a flight simulator for training pilots that is approved by the Ministry of Land, Infrastructure, Transport and Tourism. We develop products in the fields that demand the highest level of technical development today: aircraft (fixed wing and rotary wing); space-related (rockets and the H-II Transfer Vehicle); the design of missile systems, vehicle equipment, and engines; and various types of analysis and evaluation. TAMADIC is a leader in state-of-the-art aerospace engineering.

Production Engineering and Production Equipment

We support cutting-edge production facilities by designing production equipment that is essential for aircraft and rocket production. This includes designing assembly jigs for aircraft (fixed wing and rotary wing), designing jigs for sheet metal and composite parts, and jig design for rocket engines and jet engines.

We also contribute to space development through our support for rocket launches and maintenance at Tanegashima Space Center.

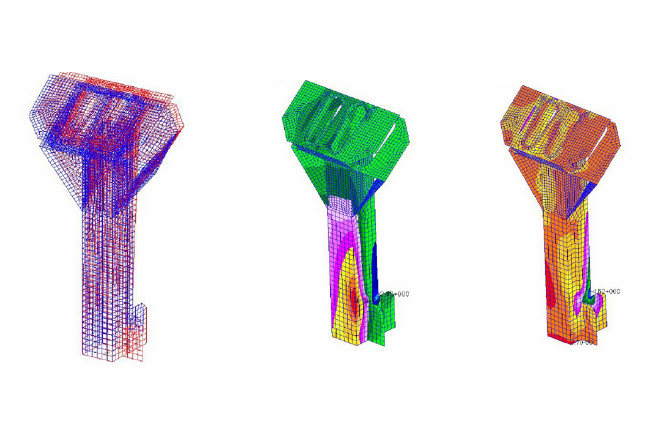

CAE Analysis Technology

We provide structural analysis technology that makes use of computer-aided engineering (CAE). We help customers reduce development times and cost while ensuring safety and quality by performing simulations to check rigidity and verify strength under various conditions at design and development sites. At TAMADIC, our CAE analysis technology services allow us to assist customers through design change proposals based on analysis results as well as the fabrication of products themselves.

Information Systems

We use software technology to provide factory digitalization services and IoT system development, and we promote smart factories and energy-saving innovations with our customers.

Research and Development

TAMADIC has launched a variety of R&D initiatives (motion systems, VR/AR/MR technology, and more), and we are working to acquire elemental technologies. We contribute to the development of the Japanese aerospace industry by pioneering future advances in aeronautics and space development based on the knowledge we have acquired through our R&D efforts.

Technical Domains

Product Development

- Development of flight simulators for pilot training

- Development of motion systems (R&D)

- Development of VR/AR/MR (R&D)

- Software development

- FEM-based analysis

- Strength analysis for aircraft, space vehicles, and missile systems

- Aircraft and rocket flight analysis

- Development support for aircraft, space vehicles, and missile systems

- Structural design for aircraft, space vehicles, and missile systems

- Electrical component design for aircraft, space vehicles, and missile systems

- Equipment design for aircraft, space vehicles, and missile systems

- Software design for aircraft, space vehicles, and missile systems

- Analysis and testing of strength, vibration, collision, and aerodynamics-related characteristics

- Rocket performance testing

- Simulation testing (flight characteristics evaluation)

- Aircraft (fixed wing and rotary wing) control system design

- Development of flight training equipment (fixed wing and rotary wing)

Production Engineering and Production Equipment

- Factory digital transformation

- IoT applications

- Design of testing equipment for aircraft, space vehicles, and missile systems

- Production equipment design and fabrication for space vehicles and aircraft

- Manufacturing tool design for aircraft, space vehicles, and missile systems

- Rocket launch support (Tanegashima Space Center)

- Tanegashima Space Center launch facility maintenance

- Quality assurance for aircraft, space vehicles, and missile systems