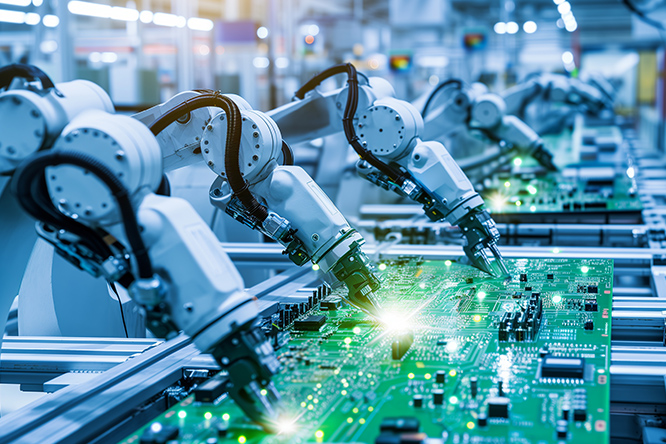

Factory Automation / Robotics

We bring together our abundant expertise for the benefit of cutting-edge manufacturing industries.

In the field of factory automation and robotics, we contribute to the achievement of a sustainable society in the future by providing advanced automation technologies that integrate mechanical, electrical, electronic, and software technologies to achieve smart manufacturing. As a robot systems integrator, we plan out and propose optimized automation solutions that utilize robotics, automated guided vehicles (AGVs), conveyors, sensors, and more in order to give our customers competitive production systems.

Highlights

Using our comprehensive engineering expertise in the fields of factory automation and robotics, we can provide broad-based support in the areas of semiconductor, LCD, and logistics conveying equipment development; development of equipment for automation, labor-saving solutions, and smart conversion; development of automatic conveyor control systems at all stages, from conceptual development to design, fabrication, and on-site construction.

Our highly skilled mechanical, electrical, electronic, and software engineers visit the customer directly, starting at the inquiry stage, to ensure prompt service.

Product Development

We provide automated conveying equipment for material handling. We propose technologies and systems for improving existing products and reducing costs, including the design of conveying equipment for general logistics used in large automated warehouses and in clean rooms such as those at semiconductor manufacturing plants.

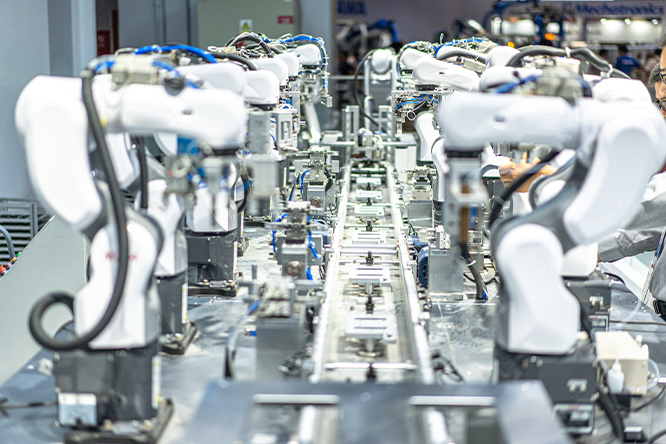

Production Engineering

Production engineering is technology related to processes for manufacturing products. Manufacturing sites require optimized production processes in which the three factors of production — quality, cost, and delivery (known collectively as QCD) — are controlled in a well-balanced manner. We offer optimized processes and systems for everything from small-scale production facilities to large-scale production lines, based on our experience in providing technical support for production processes in such diverse fields as automobiles, aerospace, factory automation, and electronics.

Robot Systems Integrator

More than ever, we’re pushing for automation and labor-saving solutions to improve operational efficiency at manufacturing sites. As an independent robotic systems integrator, we listen to end users to understand their automation and labor-saving goals as well as their product manufacturing requirements in great detail. As professionals in production equipment setup, we propose the introduction of mechanical systems that utilize the most suitable robots among the many industrial robots available, and we provide optimal production systems that combine mechanical, electric, and software technologies. We also ensure proper protection of the information assets provided during system investigation by signing non-disclosure agreements (NDAs) in advance.

Information Systems

Information systems manage information related to people, products, and equipment at factories. They are broadly divided into management systems used for production activities (information technology, or IT) and control systems that control and operate processing equipment (operational technology, or OT).

By linking these various management systems (information networks) with control systems (control networks), we facilitate the development of information systems that can receive production instructions from production control systems, that can monitor process data and equipment data, and can achieve product traceability.

Technical Domains

Product Development

- Design of automated warehouse conveyor equipment

- Design of semiconductor conveyor equipment

- Design of LCD conveyor equipment

- Development and design of large industrial printers

- Design of industrial machinery and service robots

- Precision equipment product design

- Precision equipment production equipment design

- Photocopier development and design

- Camera component development and design

- Analysis and strength calculation for various types of components

Production Engineering

- Construction equipment welding jig design

- Printed circuit board mounting machines

- Design and manufacture of various measuring machines

- Electrical control device design and manufacture

- Assembly jig design

- Automated assembly equipment design

- Automated camera module assembly equipment design

- Design of automatic nozzle processing and assembly for ink jet heads

- Wafer manufacturing equipment design

- Robot design and fabrication

- End effector (robot hand) design

Robot control programs

Robot teaching

Robot system simulations

Robot mount design

Conveyor equipment design

- Transfer equipment design

- Jig design

- Control design (programmable logic controllers and touch panels)

- Electrical design (control circuits and electronic circuits)

- Image processing technology

- Sensing technology

- Tracking technology

- IoT applications

- Palletizers

- Pickers

- Inspection instruments

- Printed circuit board functionality-based and imaging-based inspection devices

Dimension inspection devices and flow rate inspection devices (liquids and gases)